Lithopone was developed in the 1870s as a substitute for lead carbonate (lead white), to overcome its drawbacks of toxicity and poor weathering resistance. Within a few years, titanium dioxide displaced lithopone to become the white pigment (PW6) par excellence in the industry and the world’s best-selling inorganic pigment. However, titanium is a product whose price is subject to large price variations due to product availability. These price increases affect the competitiveness of finished products, and so the search for an alternative to titanium dioxide has generated a variety of possibilities to optimise its use.

Lithopone, an alternative to titanium dioxide

Lithopone is a white pigment (PW5) co-precipitated from solutions of zinc and barium salts according to the following reaction:

ZnSO4 – BaS ➔ BaSO4*ZnS

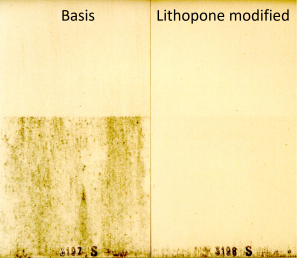

Thanks to its rheological and optical properties, Lithopone 30% offers both technical and economic advantages in the substitution of titanium dioxide in different applications. Among these advantages, it has been observed that Lithopone 30% has algaecidal properties in paints, which gives greater protection to the coating.

Studies have been carried out with both emulsion paints and powder paints, both with clear results on how the use of Lithopone 30% reduces the appearance of algae in the paint once it has been applied (see photos).

Lithopone 30% complies with both the REACH and Indirect Food Regulations, as well as with many European regulations regarding Toys, Packaging, Resins, etc…

The applications in which it can be used are paints, inks, plastics, elastomers, paper, fillers, adhesives…

Partial substitution of titanium dioxide in liquid paints

Lithopone 30% has a lower coverage power than titanium dioxide. For this reason, Lithopone 30% can only partially substitute titanium dioxide, between 5 and 40%.

Below 20% substitution, it is recommended to replace 1 kg of TiO2 with 1 kg of Lithopone.

Above 20%, it is recommended to replace 1 kg TiO2 with 1.3 kg of Lithopone 30%.

In order to achieve the same solids content, the larger filler and the binder should be reduced if necessary.

By doing so, we achieve cost reduction, increased film strength and improved fungicidal and algaecidal properties.

Example of partial substitution of titanium dioxide with Lithopone 30% in a liquid paint.

| Component |

|---|

| Water | ||||

| Thickener (Celluoseether) | ||||

| Dispersing Agent, Acrylic | ||||

| Lithopone | ||||

| TiO2 | ||||

| CaCO3 | ||||

| Binder | ||||

| Additives (Biocide, pH Corr., Antifoam, etc.) |

Lithopone in plastics and masterbatch

Lithopone 30% increases extruder performance and reduces processing costs, improves quality and is suitable for masterbatch for injection of Polyolefins, ABS, Polycarbonate, Polypropylene, Polyethylene, Polystyrene, single layer films, multi-layer films and for white, coloured and filled masterbatch. The combination of Lithopone 30 with TiO2 results in improved mechanical properties including higher elongation values and better impact resistance.

Lithopone 30% applied in masterbatch has maximum purity, good opacity and reasonable light fastness.

Below 10% substitution, 1 kg of TiO2 should be replaced by 1 kg of Lithopone 30%.

Above 10%, 1 kg of TiO2 should be replaced by 1.3 kg of Lithopone 30%, reducing the amount of polymer accordingly.

Example of partial substitution of titanium dioxide with Lithopone 30% in a white masterbatch

| Polymer | ||||||

| TiO2 | ||||||

| Lithopone | ||||||

| Additives | ||||||

| Total composition % | ||||||

| Ashes % |

Lithopone in natural and synthetic elastomers

Lithopone 30% is a perfect alternative to titanium dioxide in all natural and synthetic pigmented elastomers, as it is non-abrasive and extremely acid resistant.

Lithopone 30%, in any type of rubber, not only reduces the cost of partial substitution of TiO2 but also increases industrial production and improves the durability and the thermal and mechanical resistance of the finished product.

Lithopone in fillers, adhesives, joints and sealants

Lithopone 30% is the perfect solution for partial substitution of TiO2 in fillers due to its very soft nature and hardly any shrinkage properties.

It is suitable as an alternative to titanium dioxide when higher acid resistance is required, such as in adhesive joints and sealants.

Do you want to know more? Contact us